Wet Wire Drawing Machine

Wet Wire Drawing Machine Specification

- Product Type

- Wet Wire Drawing Machine

- Power Source

- Electricity

- Usage & Applications

- Industrial

Wet Wire Drawing Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 2 Units Per Month

- Delivery Time

- 7-15 Days

- Main Domestic Market

- All India

About Wet Wire Drawing Machine

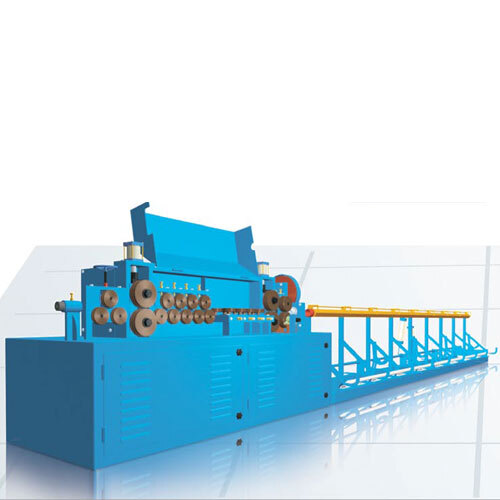

Wet Wire Drawing Machine

We offer state-of-the-art Wet Wire Drawing Machine to draw intermediate wires & fine wires from Ferrous Metals, Non Ferrous Metals and Metal Alloys. Machines suitable for high-speed drawing are available with optional swiveling Die Holders, Tungsten Carbide Cone Rings for very long service life, special Lubricant Cooling System & fully adjustable exit Die Holders.

Available in different Capstan Diameters and Spool Sizes, these machines have multi-spindle and multi-die combination, which suit best with oil based lubricants. We also provide complete accessories and spares parts as well as custom designing to meet clients' needs.

Features:

- For drawing Mild Steel, Carbon Steel, Stainless Steel, Copper, Aluminum and their Alloys

- High speed Timing Belts transmission for power saving or highly efficient Alloy Steel hardened & ground helical gear drive.

- Solid Tungsten Carbide drawing cones for very long service life or Alloy Steel T.C. Coated drawing cones for economy.

- Submerged lubrication or splash lubrication options.

- Support cone or all drawing cone design.

- Lubricant cooling system with highly efficient insulated plate type heat exchanger or through centralized lubrication system.

- Cones Shaft Assemblies are easily removable for maintenance and having centralized grease lubrication option.

- Dancer System at wire exit for providing synchronization of wire collection at spooler.

- Horizontal Spooler as per required weight with pneumatic clamping or mechanical screw clamping.

- Option to operate the machine in tandem with multi pass dry drawing machines.

- Re-Circulation of lubricant is performed by means of fluid pump, overflow and manual release valve.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in other Category

Vertical Wire Spooling Machine

Minimum Order Quantity : 1 , , Unit

Usage & Applications : Industrial

Product Type : Vertical Wire Spooling Machine, Other

Power Source : Electricity

Operating Type : Automatic

Inverted Vertical Drawing Blocks

Minimum Order Quantity : 1 Unit

Usage & Applications : Industrial

Product Type : Other, Inverted Vertical Drawing Blocks

Operating Type : Automatic

Inline Descaling Systems

Minimum Order Quantity : 1 Set

Usage & Applications : Industrial

Product Type : Other

Power Source : Electricity

Operating Type : Automatic

Wire Straightening and Cutting Machine

Minimum Order Quantity : 1 Unit

Usage & Applications : Industrial

Product Type : Other, Wire Straightening and Cutting Machine

Power Source : Electricity

|

ASSOMAC MACHINES LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry